Understanding Commercial Refrigeration: Answers to Common Questions

October 29, 2025If you manage a restaurant, grocery store, or food storage facility, your refrigeration system isn’t just another appliance. It’s the backbone of your business. Proper commercial refrigeration service ensures compliance with FDA food safety regulations, energy efficiency, and reliable temperature control that protects your inventory and your bottom line.

At Refrigeration Control Co., our certified technicians specialize in the installation, maintenance, and repair of advanced commercial refrigeration equipment throughout Southern California.

In this post, we’ll answer some of the most common questions business owners ask, covering topics like pump-down systems, temperature swings, refrigerant choices, and installation costs.

Contact us with any questions or to request service.

Frequently Asked Questions About Commercial Refrigeration

What is a pump-down system and why is it used in commercial refrigeration?

A pump-down system isolates refrigerant in the receiver when the system is off, preventing liquid refrigerant from migrating into the compressor. This protects the compressor from potential damage caused by liquid slugging and reduces refrigerant loss during service.

Common configurations include single-compressor systems, rack systems, and split systems.

While pump-down setups improve reliability and simplify maintenance, they may cost more upfront due to additional valves and controls.

Understanding Pump-Down System Types

Pump-down systems are an important part of commercial refrigeration equipment, helping prevent liquid refrigerant from migrating into the compressor during off-cycles and protecting the system from potential damage.

Depending on your facility size, cooling load, and layout, installers may recommend different configurations. Below is a breakdown of the most common commercial refrigeration system types (single-compressor, rack, and split systems) and how each one operates, along with their advantages and considerations.

Types of Pump-Down System Configurations Explained

| Comparison of Common Pump-Down System Configurations | ||||

| System Type | Description | Best For | Advantages | Considerations |

| Single-Compressor System | A single compressor controls the entire refrigeration circuit. When the thermostat is satisfied, the liquid line solenoid closes and the compressor pumps refrigerant into the receiver until the low-pressure control shuts it off. | Small to mid-size coolers, freezers, or display cases with moderate load demand. | – Simple design and lower installation cost. – Easier to service and maintain. – Efficient for light to medium applications. | – Limited capacity control. – If the compressor fails, the entire system is down. – Less efficient for variable loads. |

| Rack System | Multiple compressors operate in parallel, serving several refrigeration circuits. Each circuit can have its own solenoid and evaporator, allowing shared capacity and redundancy. | Supermarkets, warehouses, or multi-zone facilities with high or fluctuating loads | – Energy-efficient through load sharing. – Redundancy reduces downtime. – Easier to expand and control. | – Higher upfront cost. – Requires more complex control and monitoring. – Larger footprint and installation time. |

| Split System | Separates the condensing unit (outdoor) from the evaporator unit (indoor). Refrigerant lines connect the two, and pump-down control can be added for safety and efficiency. | Businesses needing flexibility between indoor and outdoor installation locations. | – Reduces indoor heat and noise. – Easier placement for space-constrained buildings. – Good efficiency and serviceability. | – Requires proper refrigerant line sizing and insulation. – More complex installation than self-contained systems. – Long line runs can affect efficiency. |

Common Commercial Refrigeration Questions and Answers

What is the temperature swing of an air-sensing commercial refrigeration thermostat?

Air-sensing thermostats typically operate with a temperature swing of 3°F to 5°F. This small range helps maintain consistent product temperatures inside walk-in coolers, freezers, and display cases. The thermostat measures the ambient air rather than product temperature, allowing quicker response to door openings and ambient changes for efficient compressor cycling.

How much does it cost to install a commercial refrigeration system in Orange County, CA?

Installation costs vary widely depending on the type of commercial refrigeration equipment, system capacity, and building design. On average, installation by a licensed commercial refrigeration installer in Orange County ranges from $10,000 to $50,000 for small to mid-size systems, while large supermarkets or industrial facilities can exceed $100,000. Obtaining a site evaluation ensures accurate pricing based on your cooling load and energy efficiency goals.

What is the best refrigerant for commercial refrigerators?

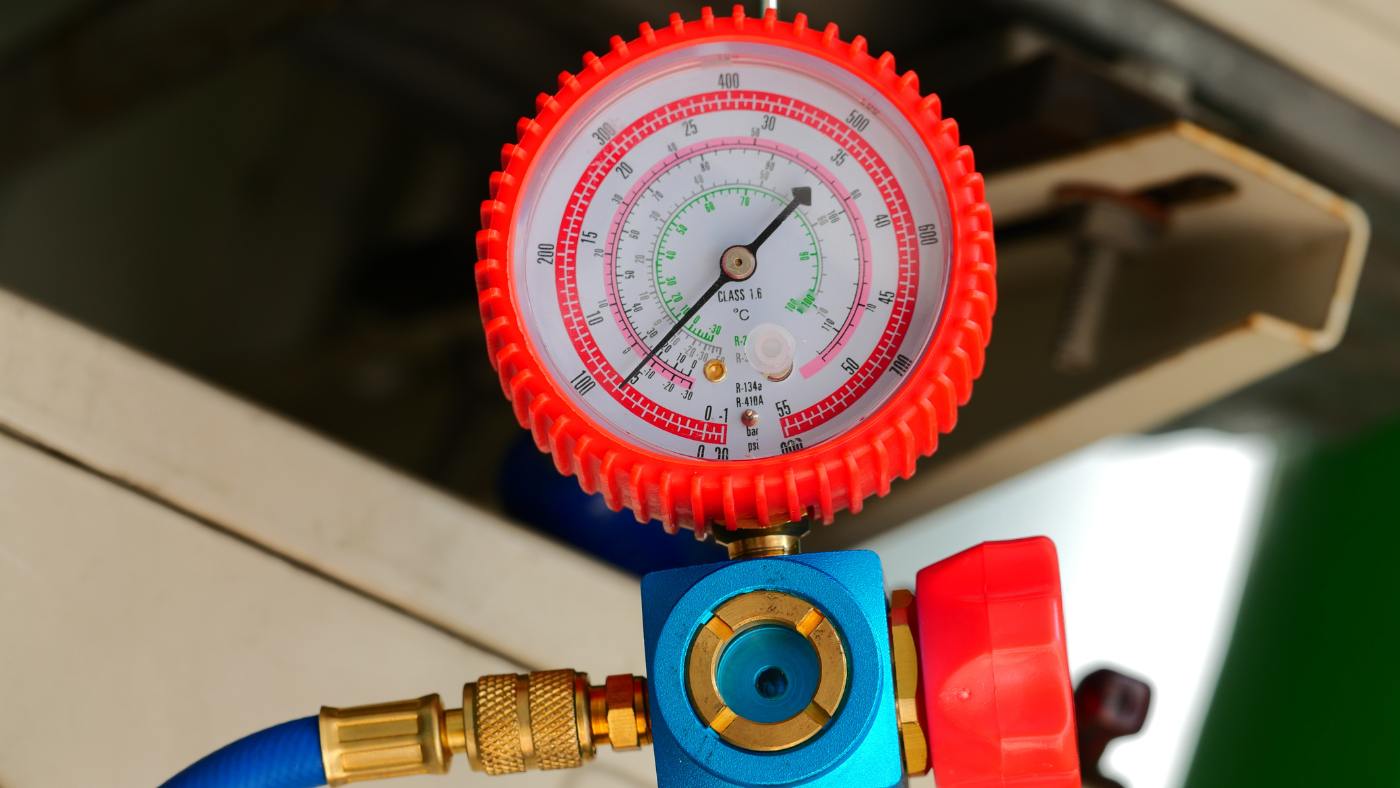

The best refrigerant depends on the application and environmental regulations. Common options include R-448A and R-449A, which offer energy efficiency and lower global warming potential (GWP) compared to older refrigerants like R-404A. For new commercial refrigeration units, natural refrigerants such as CO₂ (R-744) and R-290 (propane) are gaining popularity due to their eco-friendly properties and compliance with California Air Resources Board (CARB) standards.

Talk to a Commercial Refrigeration Expert in Southern California

Choosing the right refrigeration system or understanding its operation shouldn’t slow down your business. Whether you’re planning a new installation, upgrading outdated equipment, or simply have questions about your current setup, the team at Refrigeration Control Company is here to help.

Our certified technicians serve Orange, Los Angeles, Riverside, and San Bernardino Counties, providing reliable guidance and expert service for all types of commercial refrigeration units. Call 1-888-RCC-8807 or contact us online to speak with an experienced commercial refrigeration installer today.